The global planogram software market is booming, projected to almost double by 2033, with a CAGR of 9.2% through 2026–2033 (Verified Market Reports). Market drivers include the rise of data-led merchandising, the shift toward omnichannel retail, and heightened demand for visual shelf optimization. Retailers are leaning on planogram software for product arrangement, visual merchandising, and space optimization. The growth is driven by the need to reduce stockouts, boost inventory turnover, and deliver superior customer experiences.

Let’s explore how these technologies are shaping the future of planogram software, driving efficiency, engagement, and profitability.

Key Technologies Driving Innovation In Planogram Software

Retailers today face major challenges in shelf planning: frequent stockouts, inefficient use of space, inconsistent execution across locations, and the growing complexity of omnichannel merchandising. With advancements in artificial intelligence (AI), augmented reality (AR), and automation, planogram software is helping solve these issues by making planning more accurate, adaptive, and data-driven. Below, we explore the major innovations driving the future of planogram software and how they address these critical challenges for retailers.

AI in Predictive Analytics & Optimization

AI is revolutionizing how planograms are created and optimized. AI-driven predictive analytics can accurately forecast demand by analyzing historical sales, customer demographics, seasonal trends, and competitor activity. This ensures that high-demand products are given premium shelf space, while slow-moving items are strategically placed to reduce waste. Retailers benefit from increased revenue per square foot and improved inventory turnover. Additionally, predictive tools can simulate multiple layout scenarios to determine which arrangement maximizes profitability.

Proactive Planogram Adjustment Using AI

Unlike static layouts, AI allows for proactive adjustments to planograms. When consumer demand shifts suddenly due to a viral trend, economic changes, or supply chain disruption, AI-powered systems can automatically suggest or implement new layouts. This real-time adaptability reduces lost sales opportunities and minimizes out-of-stock situations.

Beyond simple adjustments, smart analytics play a central role by continuously monitoring sales data, basket analysis, and shopper behavior patterns. These insights help retailers prioritize high-margin items, anticipate shifts in product popularity, and optimize planograms to reflect evolving trends. Some systems even integrate external factors such as weather forecasts or social media trends, enabling retailers to anticipate demand before it peaks and act with precision rather than reaction.

3D Planogram Automation

Automation has drastically reduced the time and resources required to design effective planograms. With 3D planogram automation, retailers can generate ultra-realistic shelf simulations within minutes. These models not only provide a clear visual reference but also allow stakeholders to walk through a digital store before any physical changes are made. This speeds up approvals, ensures layout consistency across multiple locations, and minimizes costly trial-and-error adjustments in physical stores. Most importantly, detailed 3D simulations give store employees a precise visual guide to follow, helping them recreate planograms on the shelves with far greater accuracy and reducing the risk of misplacement or human error.

AR-Guided Implementation

Augmented reality (AR) is enhancing the execution of planograms at the store level. Using smartphones, tablets, or AR glasses, employees can overlay digital instructions directly onto shelves. This guides them step by step in placing products exactly where they belong, ensuring a higher level of accuracy during planogram recreation on the shelves. By providing a real-time digital overlay, employees no longer need to interpret 2D diagrams or written instructions, which often led to errors. AR reduces training time, eliminates interpretation mistakes, and improves compliance rates by making directions more intuitive and precise. For retailers, this translates into faster rollouts of new promotions or seasonal displays, reduced employee error, and greater consistency across all stores.

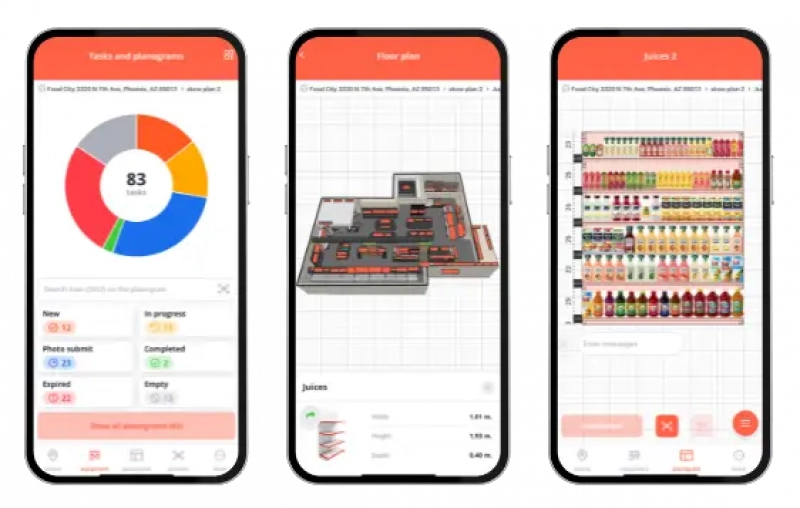

Cloud-Based and Mobile Planogram Planning

The rise of cloud technology has made planogram collaboration easier than ever. Corporate teams, regional managers, and store-level staff can access and update layouts in real time from anywhere. This eliminates the bottlenecks of traditional systems, where updates had to be distributed manually. On the mobile front, associates on the sales floor can instantly view the latest layouts on handheld devices, ensuring alignment with headquarters’ strategies. Mobile apps also allow associates to upload compliance photos, creating a feedback loop that ensures continuous accuracy.

Omnichannel Synchronization

In the age of hybrid shopping, planogram software must go beyond physical stores. Omnichannel synchronization ensures that product placement in brick-and-mortar stores mirrors online catalogs and promotions. This consistency builds customer trust and creates seamless experiences across touchpoints—whether customers are browsing online, reserving for pickup, or shopping in person. For retailers, this alignment reduces discrepancies, improves click-and-collect efficiency, and ensures smooth promotional rollouts across digital and physical platforms.

IoT and Computer Vision Monitoring

IoT sensors and computer vision systems are transforming compliance monitoring. Cameras and smart sensors can automatically detect whether shelves match planogram layouts. For example, if a product is misplaced or running low, the system sends an alert to staff to restock or correct the issue. These technologies not only improve accuracy but also reduce the need for manual audits. Advanced systems can even measure customer interactions with products, providing valuable insights into shopper behavior.

Automatic Shelf Audits Using Computer Vision

Manual shelf audits are time-consuming and prone to errors. By integrating computer vision with AI, planogram software can automatically scan shelves, identify compliance gaps, and generate instant reports. These audits capture missing items, misplacements, and pricing errors with accuracy levels often exceeding 90%. Combined with task management tools, the system can assign corrective actions to employees in real time. This automation not only saves labor costs but also ensures that stores maintain brand standards and optimal customer experiences consistently.

A standout example is LEAFIO’s AI planogram image recognition: it analyzes shelf photos, flags deviations via color-coded maps, and automatically generates corrective tasks in the mobile app—streamlining compliance and ensuring shelves stay stocked and optimized

Conclusion

AI, AR, and automation are shaping the evolution of planogram software. These technologies are enabling predictive planning, real-time adjustments, immersive visualization, and intelligent compliance monitoring. Retailers who embrace these innovations will gain a competitive edge through improved efficiency, stronger brand consistency, and enhanced customer experiences.

Post Comment

Be the first to post comment!