Table of Content

- Why AI Sales Insights Are Becoming Essential for Modern Manufacturing

- Smarter Demand Forecasting Starts With AI-Driven Sales Data

- Optimizing Production Planning With AI Sales Insights

- AI Tools That Support Manufacturing Decisions

- Challenges and the Role of Human Expertise

- Turning AI Insights Into Operational Advantage

Manufacturing planning has long leaned on experience, gut instinct, and fixed forecasts. That approach used to work fine when markets were steady, but now, with demand swinging, margins shrinking, and supply chains tangled, it’s turning into a real risk. Here’s where AI-driven sales insights tip the balance.

Artificial Intelligence studies both live and past sales data to spot demand shifts sooner, match production with real market signals, and react fast when orders start spiking. Rather than scrambling after problems pop up, teams can plan ahead by streamlining work, cutting waste, and shaping systems sturdy enough to handle sudden twists.

Why AI Sales Insights Are Becoming Essential for Modern Manufacturing

Wild swings in demand, tighter deadlines, and rising costs have turned gut-feel planning into a shaky bet. AI-driven sales insights give manufacturers the clear view they need to make smart decisions, turning guesswork into steady, data-backed planning instead of scrambling to put out fires.

• What AI Sales Insights Really Mean for Manufacturers Today

Manufacturing companies can use AI sales insights to understand their sales activity better and get clear, actionable signals out of them. The AI does not only report the sales of the last quarter; rather, it looks at the patterns, trends, and buyer behavior to predict what will be sold next.

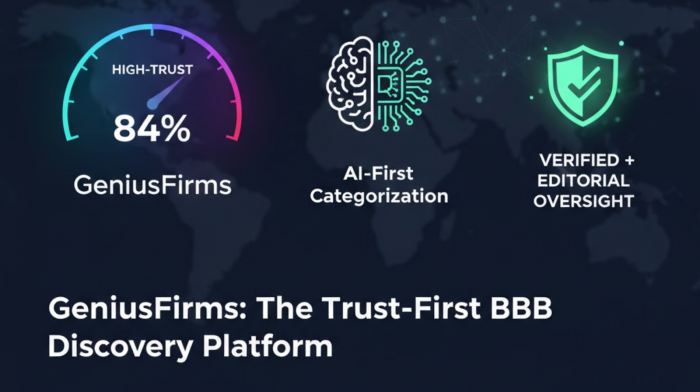

A key input here is understanding what lead generation is: the process of finding and attracting new buyers, and why lead quality matters. High-intent leads signal real demand, not just interest. Platforms like Qualified emphasize this distinction, and for manufacturers, it means that their production plans are now based on reliable demand sources rather than on overhyped or speculative demand forecasts.

• How Sales Intelligence Connects the Shop Floor to the Sales Pipeline

Sales intelligence connects commercial teams with operations, turning shared data into the link that keeps everything running smoothly. When marketing and sales data feed straight into the planning system, production choices match what buyers really want; you can almost see the orders stacking up instead of guesses filling spreadsheets.

This alignment keeps manufacturers from wasting effort, like cranking out parts for deals that never land, or losing chances because they’re too slow to respond. When everyone can see the same data, sales teams grasp their limits, and production crews know exactly how much demand is on the horizon.

The outcome is tighter coordination, fewer unexpected hiccups, and a production floor that reacts smoothly.

• Turning Sales Data Into Actionable Production Signals

Manufacturing companies can use their sales data in a significant way only when it leads to the production of clear and definite actions. AI is assisting producers in identifying the changes quickly to make concrete planning decisions. This is the point where integrated systems become important.

For instance, MRPeasy's small business ERP software is designed to bring sales orders, inventory data, and production schedules into one view. Such visibility in operation allows the teams to change batch sizes, order materials, or reschedule production runs before issues arise.

So, instead of being forced to respond to stockouts or excess inventory, manufacturers are in a position to closely match their output with the real demand signals.

Smarter Demand Forecasting Starts With AI-Driven Sales Data

Precise demand forecasting lays the groundwork for smooth, efficient production. AI sharpens the process by spotting patterns and odds that human forecasts often overlook, turning a jumble of sales numbers into a steadier guide for planning.

• Using Machine Learning to Predict What Customers Will Actually Buy

Machine learning models analyze loads of sales data from the past to uncover trends on what is seasonal, product lifecycles, and even customer behavior. Compared to regular forecasts, these models keep learning and getting better with every new piece of data. They can account for variables like promotions, regional differences, or changing buyer preferences.

For manufacturers, this means forecasts that reflect reality more closely. Instead of relying on average results or making guesses, planners get probabilistic insights that allow them to make better decisions on capacity planning, workforce allocation, and procurement; thus, the risk of expensive surprises is minimized.

• Spotting Demand Patterns and Market Shifts Before They Hit Production

AI is very good at spotting the small changes that can easily be overlooked when using conventional methods of reporting. For instance, a gradual increase in questions, shorter sales cycles, or higher repeat orders can all be indications of changing demand.

Once these trends are spotted at the earliest stage, producers have the opportunity to revise their manufacturing schedules to avoid situations of overflows or a lack of products. Such a function of early warning is highly appreciated in unstable markets, where a delayed response may result in lost sales or surplus inventory.

So, through the use of real-time insights, the teams can take the initiative instead of being forced to react, which leads to the improvement of both the company's service levels and its operational stability.

• Building More Reliable Demand Plans With AI Insights

Accurate demand planning alone is not enough; it also requires balance. AI enables producers to synchronize expected demand with available capacity, workforce, and raw materials. Through the use of various scenarios, staff members are able to weigh the pros and cons and prepare for both the most favorable and the most unfavorable situations.

In this way, the danger of excessive production that uses up cash and insufficient production that annoys customers is minimized. Gradually, the use of AI in planning becomes a source of trust between different departments as it fosters a common perception of what can actually be expected and accomplished based on data rather than optimism.

Optimizing Production Planning With AI Sales Insights

Production planning takes what we learn and turns it into action. AI turns sales insights into action, shaping schedules, guiding resources, and streamlining workflows, so operations run smoother, shift faster, and match real demand.

• Production Planning Turns Insights Into Action

AI tools ensure operations become more efficient, adaptable, and responsive to real demand as sales intelligence continually informs schedules, resources, and workflows.

Manufacturers avoid bottlenecks and overproduction, and are elevating their overall operational efficiency by directly connecting production with real-time sales data.

• Smarter Production Scheduling

AI-driven scheduling helps to keep production flow smooth by aligning the time of each shift with the expected demand and the most valuable orders. Dynamic adjustments allow planners to be very quick in their response to changes in the situation.

The point at which schedules correspond with actual demand results in a situation where deliveries are made on time, machines operate with less effort, and the entire production floor is energized and faster than before.

• Inventory Optimization and Cost Reduction

Inventory is a major cost driver. AI insights help to keep the shelves stocked in the right quantity by constantly changing reorder points, safety stock, and timing according to the sales figures of the day.

When inventory is equal to actual demand, the company wastes less material, which would otherwise need to be reworked; the results become clear and measurable, shortages disappear, money moves easily, and storage costs are reduced.

• Strengthening the Supply Chain With AI Insights

AI reaches past the factory floor, linking instantly with suppliers, delivery teams, and distribution hubs to keep everything in sync. When sales forecasts flow into supply chain planning, procurement stays in step with real demand, reducing last-minute scrambles and keeping deliveries steady.

Predictive analytics spots trouble before it hits, so teams can plan ahead, keep production steady, and protect service levels.

• Synchronizing Inventory, Suppliers, and Delivery

Inventory, supplier schedules, and delivery timelines are kept in line by sales-driven planning. This being in tune shortens lead times, sharpens delivery accuracy, and lessens the costs of buffer stock or expedited shipments.

Manufacturers are able to fulfill customer expectations and, at the same time, keep their operations efficient and cost-effective.

AI Tools That Support Manufacturing Decisions

Modern AI technologies transform complicated operational data into real-time insights. Trends and exceptions are made visible through dashboards, thus enabling quicker decisions regarding production, resources, and performance.

Moreover, AI is a source of adaptive execution capability, which equips teams with the means of reacting to interruptions rapidly, preserving the flow of work and further development.

Challenges and the Role of Human Expertise

The adoption of AI is contingent upon the availability of high-quality data, integration of systems, and the readiness of the organization. The role of humans cannot be eliminated even with the presence of sophisticated tools, as they are still needed for providing context, supervision, and strategic judgment.

Leading manufacturers, who achieve the best results, merge AI-driven insights with seasoned decisions, making well-rounded, accountable decisions.

Turning AI Insights Into Operational Advantage

One of the breakthroughs in manufacturing is the use of AI to derive sales insights. AI is enhancing the whole manufacturing process from production planning, inventory management, to supply chain coordination, making the teams efficient and result-oriented.

Manufacturers who take advantage of these data-driven insights and make it their norm have the potential to extend their business, resist any changes, and stay ahead of the competition in the markets that are becoming more and more complex and volatile.

Author bio

Rilwan Kazeem is a creative writer. He has worked in social media, content marketing, and SEO for four years. He has covered topics in multiple niches, including digital marketing, HR, emerging technologies, and their intersection with business. In his leisure, he loves to meditate and spend time with his family.

Post Comment

Be the first to post comment!