Table of Content

- What Is Warehouse Management System Software?

- What Is a Warehouse Management System (WMS)?

- Why Does a Business Need WMS Software?

- What Types of WMS Software Are There?

- What Are the Must-Have Features in a Modern WMS?

- How Much Does WMS Software Cost?

- Who Are the Leading WMS Providers in 2025?

- What Are the Common Implementation Challenges?

- Real-World Case Study: How a 3PL Cut Costs with WMS

- Is WMS Right for You?

- Final Thoughts

What Is Warehouse Management System Software?

Managing a warehouse is no longer just about storing products. It’s about optimizing space, speeding up operations, and delivering on time—all while minimizing costs. That’s where Warehouse Management System (WMS) software comes in.

But what exactly does it do? And how do you know if your business needs one?

Let’s break it down.

What Is a Warehouse Management System (WMS)?

A WMS is a software solution that helps businesses manage, control, and optimize daily warehouse operations. These operations include inventory tracking, order fulfillment, labor management, and shipping.

A WMS connects with other systems like Enterprise Resource Planning (ERP) and Transportation Management Systems (TMS) to create a seamless logistics network.

Key functions include:

- Real-time inventory tracking

- Order picking and packing automation

- Inbound and outbound shipment coordination

- Barcode and RFID scanning support

- Reporting and analytics dashboards

Why Does a Business Need WMS Software?

The rise in e-commerce has changed the way warehouses operate. Consumers now expect same-day shipping and real-time tracking. Manual tracking just doesn’t cut it anymore.

So what are the benefits of WMS software?

- Accuracy in Inventory

A WMS provides real-time visibility into stock levels, reducing stockouts or overstocks. According to a study by Logiwa, companies using WMS software saw inventory accuracy improve by over 99%. - Faster Order Fulfillment

With automated picking routes, barcode scanning, and real-time updates, businesses using WMS can reduce fulfillment time by up to 30%, as per Zebra Technologies. - Lower Operational Costs

WMS solutions identify inefficiencies. For example, they can analyze labor productivity or shelf space usage. This allows warehouses to cut unnecessary steps and save up to 20% on labor costs (Supply Chain Quarterly).

What Types of WMS Software Are There?

There are several types of WMS software, each suited for different business sizes and industries.

- Standalone WMS

Best for: Small to mid-sized businesses

This software focuses only on warehouse management and isn’t integrated with other systems. - Cloud-Based WMS

Best for: Businesses looking for flexibility and scalability

Cloud WMS systems like NetSuite WMS or Fishbowl Inventory can be accessed from anywhere and often come with lower upfront costs. - Integrated WMS (Part of ERP Systems)

Best for: Medium to large enterprises

These systems, such as SAP Extended Warehouse Management or Oracle WMS, are part of broader ERP suites. - Open-Source WMS

Best for: Tech-savvy teams with custom needs

Examples include Odoo, OpenBoxes, and ERPNext. These offer high customization but require in-house development expertise.

What Are the Must-Have Features in a Modern WMS?

When evaluating WMS software, these features are critical:

- Inventory Visibility: Real-time tracking across multiple warehouses

- Automated Replenishment: Set rules to reorder stock before it runs out

- Mobile Access: Use on tablets and handheld scanners

- Multi-Channel Fulfillment: Handle online, retail, and wholesale orders in one system

- Analytics and KPIs: Measure picking accuracy, inventory turnover, and order cycle time

- Returns Management: Simplify reverse logistics and restocking

How Much Does WMS Software Cost?

WMS pricing varies by type, size, and customization needs.

| Type | Estimated Monthly Cost |

|---|---|

| Cloud WMS (e.g., ShipBob, Zoho) | $300–$2,000/month |

| On-Premise (e.g., SAP EWM) | $10,000+ license fee, plus setup |

| Open-source (e.g., Odoo) | Free to use, but setup costs apply |

Implementation costs can be significant—ranging from $10,000 to $100,000, depending on the warehouse size and complexity.

According to a McKinsey report, businesses usually see ROI within 12 to 24 months after implementing a WMS.

Who Are the Leading WMS Providers in 2025?

Here’s a look at the top-performing WMS solutions on the market:

| Provider | Best For | Key Features |

|---|---|---|

| NetSuite WMS | Mid-size to large businesses | ERP integration, cloud-based, mobile access |

| Fishbowl Inventory | Small manufacturers and retailers | Inventory + manufacturing tracking |

| ShipBob | E-commerce brands | Fulfillment + WMS hybrid |

| Oracle WMS Cloud | Enterprise-level operations | AI-based optimization, robust analytics |

| Zoho Inventory | Startups and SMBs | Affordable, multichannel sales |

What Are the Common Implementation Challenges?

Even though WMS software promises efficiency, the implementation can be tricky. Common hurdles include:

- Change resistance: Staff may resist new workflows

- Poor data migration: Dirty or incomplete data leads to errors

- Underestimating training: It takes time for teams to learn new systems

- Integration issues: Especially if ERPs and shipping platforms aren't aligned

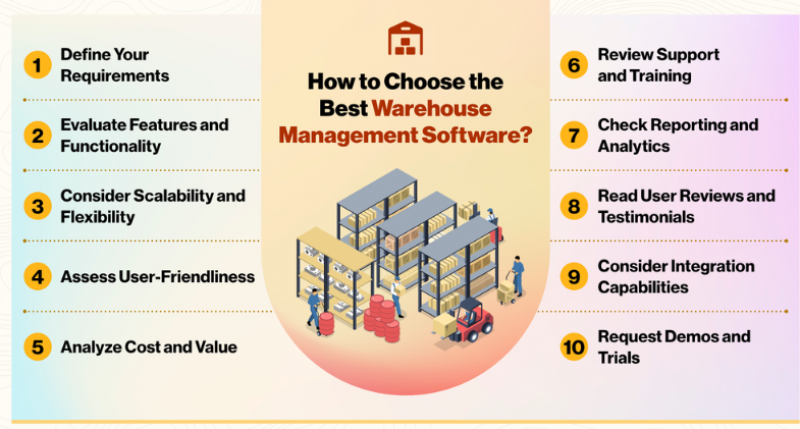

To avoid these issues, it's critical to conduct a needs assessment and select a WMS with solid customer support and integration capabilities.

Real-World Case Study: How a 3PL Cut Costs with WMS

A 3PL provider in Texas implemented Fishbowl Inventory and automated 70% of its picking operations. Within 6 months:

- Order accuracy rose from 89% to 99.7%

- Labor costs dropped by 15%

- Warehouse capacity increased by 18%

You can read more about WMS success stories at Fishbowl’s case studies page.

Is WMS Right for You?

Ask yourself:

- Do you track inventory manually or with spreadsheets?

- Are order errors and delays hurting your customer satisfaction?

- Is your current system struggling to support growth?

- If you answered yes to any of these, a WMS could drastically improve your operations.

Final Thoughts

In 2025, a Warehouse Management System isn’t a luxury—it’s a necessity. With real-time inventory tracking, labor optimization, and better order accuracy, WMS software gives you a competitive edge.

But choosing the right one depends on your budget, team size, and growth goals.

Start by evaluating your current workflows. From there, look for software that supports automation, integrates with your platforms, and scales with your business.

Post Comment

Be the first to post comment!