Crop processing is no longer stuck in the past. The days of slow, manual trimming and sorting are quickly being replaced by machines that work faster, think smarter, and never need a coffee break. Thanks to major advances in precision engineering, farms, and processing facilities are transforming how they handle post-harvest work—from a labor-heavy grind to a streamlined, tech-driven operation.

In this article, we explore the innovations that are changing the game. Technology is making crop processing more efficient, scalable, and far less stressful, from smart sensors to adaptive cutting tools. Whether you're managing a large grow or just curious about where agriculture is headed, these tools are reshaping the future. And the best part? They’re doing it one perfectly timed move at a time.

The Rise of Intelligent Crop Handling Systems

Modern crop processing is entering a new era with the rise of intelligent handling systems. These advanced machines use automation and smart sensors to manage tasks like sorting, cutting, and packaging with impressive speed and accuracy. By reducing the need for constant manual input, they help producers save time and labor costs while boosting overall output. Many systems can also adapt to different crop types and sizes on the fly, ensuring greater flexibility. This level of precision significantly reduces waste and human error, resulting in cleaner, more consistent product quality that meets today’s high industry standards.

Next-Level Crop Trimming

As the industry grows, so does the need for trimming systems that can handle high volumes while staying precise. Many growers are now turning to solutions that can process large amounts of product without sacrificing quality. Thanks to technology, we now have equipment that can do just that. Mobius cannabis trimmers, for instance, are built to deliver clean, consistent cuts while reducing downtime and manual handling. With a modular design, tool-free cleaning, and commercial-grade performance, they help operations scale up with ease. They’re widely used by cultivators who want better efficiency without losing quality in the trimming process.

Robotic Sorting and Grading Systems

Sorting is one of the most time-consuming parts of crop processing. Robotic systems now use cameras and sensors to identify each item's size, shape, and color. They then sort crops into categories automatically. This leads to faster results and higher accuracy compared to manual sorting. These systems are also useful in maintaining product consistency, especially in larger operations where worker volume can be overwhelming.

Data-Driven Processing Platforms

Smart platforms are being used to collect and analyze data during the entire processing cycle. This includes things like moisture levels, yield rates, and quality metrics. With this information, operators can make better decisions in real-time. These systems often use cloud-based tools and dashboards, making it easier to track performance and spot problems early. The result is better planning, fewer mistakes, and smoother day-to-day operations.

Adaptive Cutting Technologies

Precision cutting tools now use software and sensors to adjust automatically to the crop type being processed. This means they can cut each batch at the right speed and pressure. It helps reduce damage and maintain quality. These systems also lower the risk of wasted material. Because the settings adjust in real-time, there’s no need for constant human monitoring, which makes them ideal for busy facilities.

Smart Conveyor and Transport Systems

Efficient movement between machines is essential in post-harvest processing. Today’s smart conveyor systems use sensors to monitor product flow in real time and adjust speed automatically, keeping operations smooth and avoiding bottlenecks. They can also detect blockages, jams, or product damage early, reducing downtime. By allowing machines to communicate during transport, these systems create a more synchronized workflow. With fewer manual tasks and less interruption, production becomes faster, cleaner, and more consistent. These features help facilities maintain better output quality while cutting unnecessary delays across the processing line.

Environmental Controls for Post-Harvest Consistency

After processing, crops must be stored in stable conditions. New technology helps control temperature, humidity, and airflow. These systems make sure that the environment stays within safe levels at all times. Even a small change in air quality can affect the final product. With automated controls, the chance of spoilage or product loss is lower. This creates a safer and more consistent output, especially when handling crops that require special storage conditions.

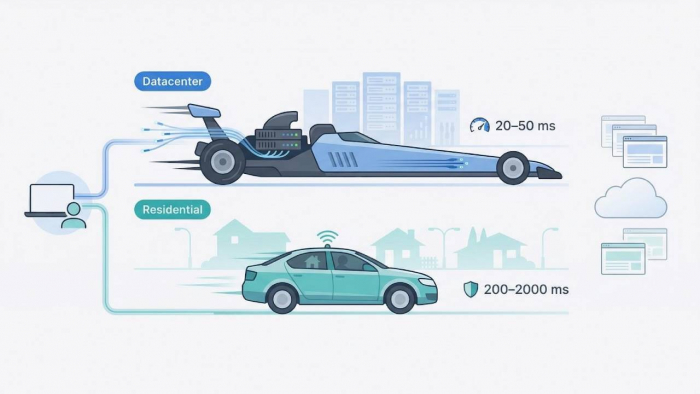

Remote Monitoring and Maintenance

Many machines now come with tools for remote monitoring. Operators can track performance from their phones or computers. This means problems can be spotted early—even when no one is near the machine. Some systems also send alerts or run updates automatically. As a result, downtime is reduced, and equipment stays in better shape for longer. Remote tools make it easier to manage multiple machines without needing extra staff on-site.

Modular Machine Design for Scalable Operations

Modern machines are built to grow with the operation. Modular designs let businesses add or remove parts based on what they need. If more trimming or sorting capacity is needed, extra units can be added easily. This saves time and money compared to buying new equipment. Modular systems also allow for faster cleaning and upgrades. For growing businesses, being able to adjust quickly is a major advantage.

Cleaner Production Through Automated Sanitation Features

Keeping machines clean is important, especially in industries where quality and safety matter. Some systems now include built-in cleaning features that reduce the need for manual scrubbing. This saves time and lowers the risk of contamination. Automatic sanitation also helps companies meet strict production standards. With fewer steps and less effort, keeping the entire line running clean and safe throughout the day becomes easier.

Precision engineering is changing how crop processing works at every level. From trimming and sorting to storage and cleaning, machines are now smarter, faster, and easier to use. Modern tools show what’s possible when design focuses on both performance and user needs. As technology continues to grow, more producers will be able to improve output, reduce waste, and handle more demand—all while keeping quality high and processes under control.

Post Comment

Be the first to post comment!